Sailboat Rigging: An expert interview with Alan Veenstra

Interviewed by Dave Rearick, Skipper of Bodacious Dream

Dave Rearick from Bodacious Dream interviews Alan Veenstra on the subject of rigging of sail boats, both new and old and the changes in technology over the years.

See two other expert interviews Dave has conducted:

:: Sailing Navigation – interviews w/ John Hoskins & Matt Scharl

:: Composite Materials Technologies – an interview w/ Lapo Ancillotti

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Dave Rearick (DR): Alan, we’ve sailed as competitors and crewmates for a number of years on various races. You also run Chicago Sailing and Rigtek. You’ve been sailing for quite some time now. Through those years I’m sure you’ve seen some amazing changes to rigging of boats. Can you give us a quick comparison of where we were thirty years ago versus where we are with technology in rigging today?

Dave Rearick (DR): Alan, we’ve sailed as competitors and crewmates for a number of years on various races. You also run Chicago Sailing and Rigtek. You’ve been sailing for quite some time now. Through those years I’m sure you’ve seen some amazing changes to rigging of boats. Can you give us a quick comparison of where we were thirty years ago versus where we are with technology in rigging today?

Alan Veenstra (AV): Modern sailboat rigging is nothing short of amazing. Before we discover why, let me start with a brief history of rigging. When man first set sail, he needed to ensure that all of the demands for safety, reliability, functionality and cost were addressed properly. Anything less would result in loss of life and property. For centuries sailing vessels relied exclusively upon natural fibers like wood, hemp and cotton for their hulls, rigging and sails. The nineteenth century was the age of iron, where wire and chain were used increasingly for hulls, masts and rigging.

Alan Veenstra (AV): Modern sailboat rigging is nothing short of amazing. Before we discover why, let me start with a brief history of rigging. When man first set sail, he needed to ensure that all of the demands for safety, reliability, functionality and cost were addressed properly. Anything less would result in loss of life and property. For centuries sailing vessels relied exclusively upon natural fibers like wood, hemp and cotton for their hulls, rigging and sails. The nineteenth century was the age of iron, where wire and chain were used increasingly for hulls, masts and rigging.

By the twentieth century, commercial sailing was economically unfeasible, but sailing survived as a sport, still utilizing the same tested technology. All this changed in about 1960. Postwar technology made boats stronger, lighter and suddenly affordable to millions of sailors. Fiberglass hulls replaced wooden hulls, as did aluminum for masts. Stainless steel replaced iron for standing rigging and hardware. Polyesters fibers like Nylon and Dacron supplanted cotton for rigging and sails. All of these second-generation ‘miracles’ were revolutionary and sailboats exploded onto the recreational scene.

The pace of technology continued to accelerate. By the 1980’s, Aramid fibers like Kevlar replaced polyester fibers, providing twice the strength at 1/5th the stretch. In the 1990s, High Modulus Polyethylene (HMPE) fibers appeared. Incredibly, they were double the strength of Aramids, with half of the stretch. Commonly known as Dyneema, this new fiber provides even more benefits; it is highly resistant to UV and chafe, yet light enough to float. About this same time, builders developed the technology to construct masts and hulls with carbon fibers, once again increasing strength and saving weight.

Slideshow – Click arrows to advance! Scroll over to read descriptions.DR: When I began sailing large boats in the 1980’s, all the hardware, and attachments were made of bronze or stainless steel. Nowadays, lightweight lashings, and low-friction rings have replaced nearly all these fittings. What brought this about?

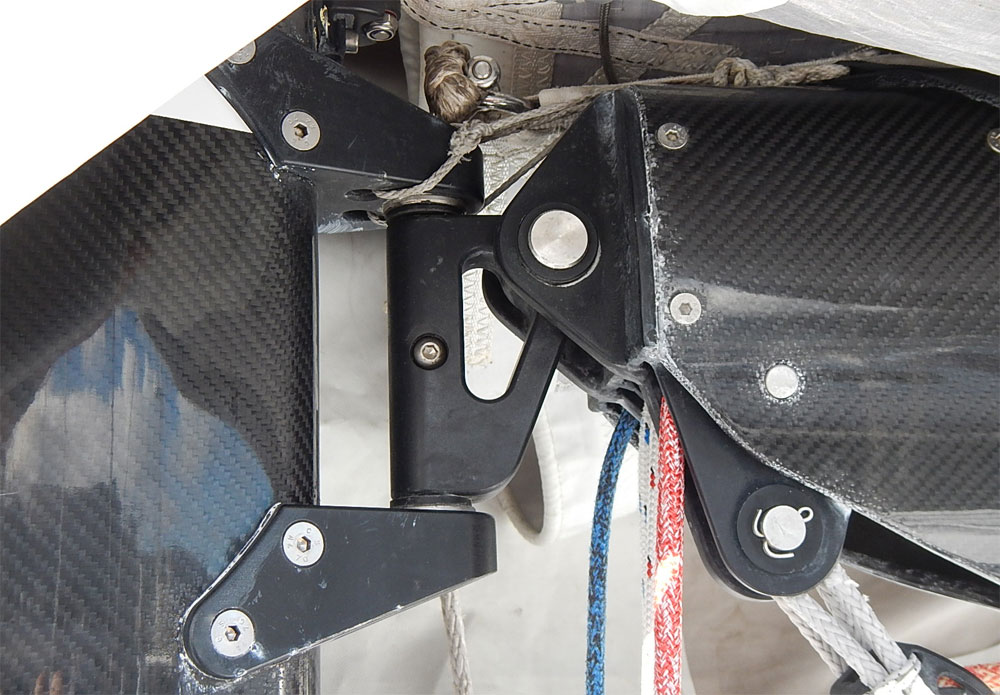

AV: You are absolutely correct; modern cordage is so strong that it has made traditional hardware nearly obsolete on high-performance sailboats. The current technological revolution is in creating strong, light hardware from composites of carbon, ceramics, and epoxy.

DR: What are some of the typical loads you might find on a Class40 racing boat like the ones raced in the Atlantic Cup? And maybe compare to the America’s Cup Cats.

AV: Ironically, a Class40 race boat often experiences lower maximum loads than a 1980’s 40 footer. This is because modern boats are capable of ‘breakaway speeds,’ which actually reduce total load. This is not as true with modern multihull race boats. Even though AC-type cats are capable of going much faster, their inherent form stability creates exceedingly high pressures in harnessing the wind. BTW, all modern boats have one thing in common; they can experience very sudden spikes in shock loading as they punch into waves at high speed.

DR: You mentioned carbon spars. The Class40 rules only allow for carbon to be used in the mast and booms of the boats. What is carbon? Is this the stuff we hear about that is bad for the environment? Carbon neutral stuff?

AV: Carbon is certainly not new. It is a basic element in nearly every aspect of modern life. While it is usually derived from hydrocarbons like oil and coal, its use as a building material does not adversely affect the environment any more than the sand and gravel that is used for cement. And in just the same way, used carbon fibers are recyclable.

DR: The mast on Bodacious Dream is all carbon. This is made by laying up various layers of carbon cloth and epoxy resins on a mandrel mold which is then cooked in an autoclave oven, producing a one-piece, composite mast. How much stronger and lighter do you think something like this is compared to an aluminum mast of twenty years ago?

AV: Carbon fibers are another technological advancement. When its unidirectional strands are impregnated with epoxy resins and cured in ovens, the resulting structure is incredibly light, strong and rigid. A modern racing mast and rigging are approximately 40% lighter than the highest tech aluminum mast. And the technology has expanded well beyond boat hulls and masts. Carbon composites are found in many everyday products, from golf clubs to airliners.

DR: As these new technologies have progressed, we have seen the size of boats grow quite a lot. Yesterday, I was reading about a 100-meter sloop; that would be over 330 feet long! What would you say about the rigging of that boat compared to a 40-foot boat like Bodacious Dream?

AV: The short answer is that 330’ sailing vessels would be completely impractical without today’s technology. The loads are astronomical, far beyond the material limits of just a few years ago. Nevertheless, you will find that those megaboats are not structurally dissimilar to Bodacious Dream, though they will rely more on exotic materials and engineering as the scope increases in size. The one major difference will certainly be that boats of such size will be completely reliant upon hydraulics for all sail handling.

DR: Have you ever experienced a major failure in rigging, losing a mast, breaking of big equipment? What is that like?

AV: I am pleased to say that I have rarely experienced mast failures, and never on a boat larger than 40’. Such events are actually far more peaceful than one would expect. Most of the time an aluminum mast simply buckles and falls over the side. Carbon masts tend to break in a more dramatic fashion, sometimes exploding at the point of fracture. These clean-ups and cutaways are traumatic and dangerous, as carbon will splinter into shards that are like razor wire.

DR: Thank you Alan, do you have any final thoughts?

AV: Yes, Dave, consider this: Sailing vessels were originally used for commercial transport. They were built and rigged with natural fibers and handled by men of iron. Today, what do we see? Modern boats are again built and rigged with fibers. Technological advancements suggest a new era of commercial sailing vessels. Yet through it all, the boats are still manned by the same breed of men. Go, Ironman!

DR: Thanks Alan, that was great!