There are few things more beautiful than the sight of a sleek boat full sail skimming across the water. But how does it all work? How do nature, science and human design come together to enable a sailboat to move in so fluid a way?

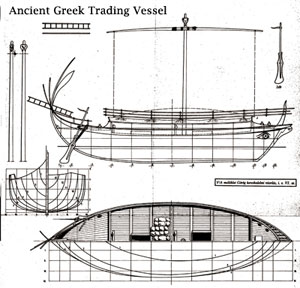

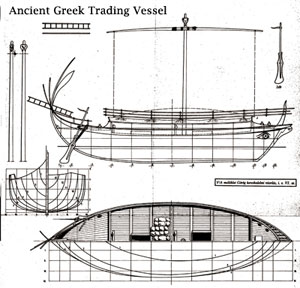

From ancient times onward, using wind power to move boats required being tuned into the ways of nature and how its many forces might be harnessed to serve human purposes. To that end, boat builders have always relied on observation and calculation, tradition, testing and passed down refinements to build their boats.

From ancient times onward, using wind power to move boats required being tuned into the ways of nature and how its many forces might be harnessed to serve human purposes. To that end, boat builders have always relied on observation and calculation, tradition, testing and passed down refinements to build their boats.

Today though, with all the incredible advances in physics, engineering, computing technology and material science, boat building (and especially racing yacht building) has become a most exciting and cutting edge industry.

To help us get up to speed on boat building today, I asked an old friend of mine, one of the world’s top racing boat naval architects, Merf Owen of Owen Clarke Designs to field some questions about his life designing boats.

To help us get up to speed on boat building today, I asked an old friend of mine, one of the world’s top racing boat naval architects, Merf Owen of Owen Clarke Designs to field some questions about his life designing boats.

You can find my whole interview with Merf RIGHT HERE, but for now, let’s imagine that I asked Merf to design a new Class 40 racer – to say, compete in the Atlantic Cup – a vessel much like the Class40 I sailed around the world a few years ago.

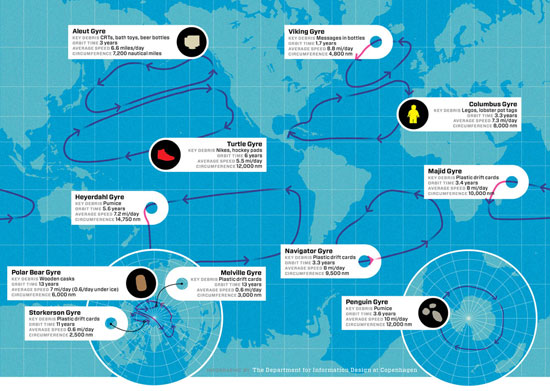

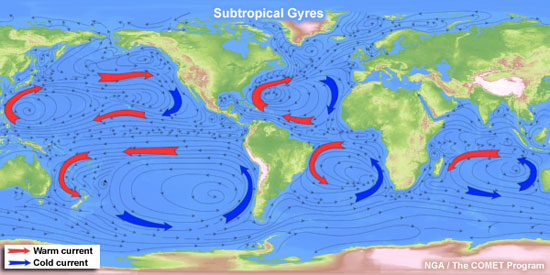

Merf would first want to know how I intend to race the boat and where in the world I plan on sailing it? My answers to these questions help provide him with guidelines for particular factors he will need to consider in designing my boat. When he learns where I want to sail the boat, he will ask a meteorologist (a weather scientist,) to study the weather patterns in those areas and so provide him with weather data (percentages of light, medium or heavier winds and the general wave patterns resulting from them.) Merf will use this information to optimize the design for those regions of the world and for the type of sailing and racing I want to do.

Merf would first want to know how I intend to race the boat and where in the world I plan on sailing it? My answers to these questions help provide him with guidelines for particular factors he will need to consider in designing my boat. When he learns where I want to sail the boat, he will ask a meteorologist (a weather scientist,) to study the weather patterns in those areas and so provide him with weather data (percentages of light, medium or heavier winds and the general wave patterns resulting from them.) Merf will use this information to optimize the design for those regions of the world and for the type of sailing and racing I want to do.

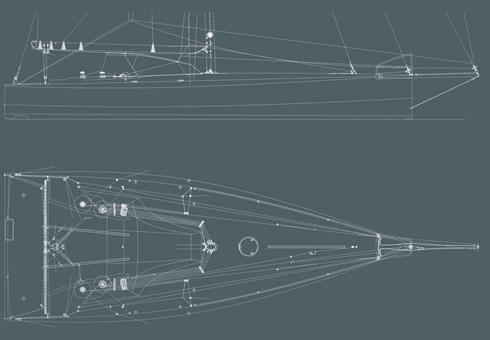

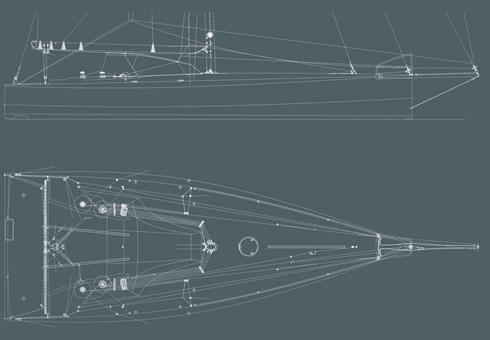

Once Merf has gathered the information he needs, he designs the shape of the hull and the “sail plan.” The hull of course is the “body” of the boat, and the sail plan is the combination of mast and sails and rigging that “power” the boat. He must align his design to the laws of physical science laws in arriving at the best shape for the hull, so that it will move through the water and waves with the least amount of “drag,” to avoid anything that slows a boat down – (like dragging your feet while riding your bike.)

One hundred years ago, a boat designer would carve the model of a boat from a wooden block – using their experience and creative instincts to determine the best shape of the hull. This model would then be converted into hand-drawn blueprints. Today, computers automate much of this process, but Merf still must exercise his intuitions and creativity to course-correct the computer output he receives.

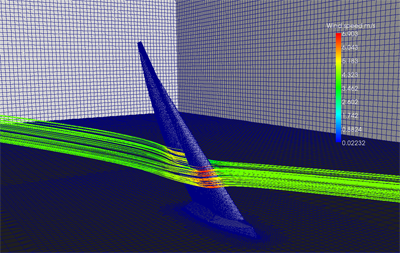

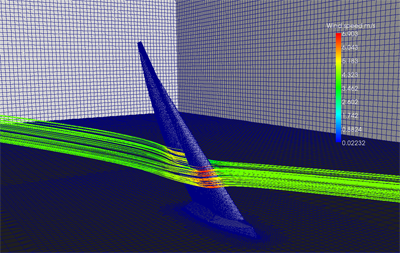

As Merf progresses with his design of the hull shape and sail plan, he can test his work using powerful computer simulation software, which shows him where modifications might help to improve performance. When he’s happy with the design, Merf emails his digital designs to the builder and the fun of boat building can commence!

As Merf progresses with his design of the hull shape and sail plan, he can test his work using powerful computer simulation software, which shows him where modifications might help to improve performance. When he’s happy with the design, Merf emails his digital designs to the builder and the fun of boat building can commence!

Once the builder reviews the design drawings, there’s much that needs to happen. You can just imagine the many things they have to figure out, and how many of them require a solid understanding of mathematics.

How much space do they need in their shop to build the boat and parts? How many layers of fiberglass cloth will be needed? How many gallons of epoxy resin? How many screws? How many people will they need to hire? How long will it take? How much is it going to cost? All of this is must be carefully figured out in order to develop a solid project plan that includes realistic cost estimates.

Once the build plan is in place, more advanced math or “engineering” phase comes into play. First the builders have to build molds in which the boat parts are cast. These molds have to be engineered strong enough to withstand people moving them around and walking on them as the boat is being built. While science, math and engineering are requirements for getting all of this correct, seasoned builders also rely on practical or “seat of the pants” engineering to build the best and strongest molds.

Once the build plan is in place, more advanced math or “engineering” phase comes into play. First the builders have to build molds in which the boat parts are cast. These molds have to be engineered strong enough to withstand people moving them around and walking on them as the boat is being built. While science, math and engineering are requirements for getting all of this correct, seasoned builders also rely on practical or “seat of the pants” engineering to build the best and strongest molds.

Once building begins, technical engineering drives the process. Structural engineers and designers figure out the details of the composite structure – the number of layers of fiberglass cloth that offer the strength to handle the “loads” (weight and forces) that various parts of the boat must support.

Here again, an understanding of physics is necessary. A rope or “line” turning through a block is a good example. The line pulls a lot of weight and when it turns around a pulley, it changes the direction of the load. The pulley has to withstand these loads and not break loose from its mounting. All these loads and attendant forces have to be calculated so that the size of the block, bolts and composite materials can withstand these always changing loads.

Here again, an understanding of physics is necessary. A rope or “line” turning through a block is a good example. The line pulls a lot of weight and when it turns around a pulley, it changes the direction of the load. The pulley has to withstand these loads and not break loose from its mounting. All these loads and attendant forces have to be calculated so that the size of the block, bolts and composite materials can withstand these always changing loads.

An even more complex set of calculations is necessary when it comes to the mast, which must support the power of the sails through the supporting cables called “shrouds.” There are many calculations to consider in how the shrouds spread the loads across the entire hull. All this has to be worked out so the boat and mast won’t fail in a powerful storm, yet still remain light enough to be competitive on the racecourse. There are always trade-offs to consider between strength and weight when making these important calculations and decisions.

An even more complex set of calculations is necessary when it comes to the mast, which must support the power of the sails through the supporting cables called “shrouds.” There are many calculations to consider in how the shrouds spread the loads across the entire hull. All this has to be worked out so the boat and mast won’t fail in a powerful storm, yet still remain light enough to be competitive on the racecourse. There are always trade-offs to consider between strength and weight when making these important calculations and decisions.

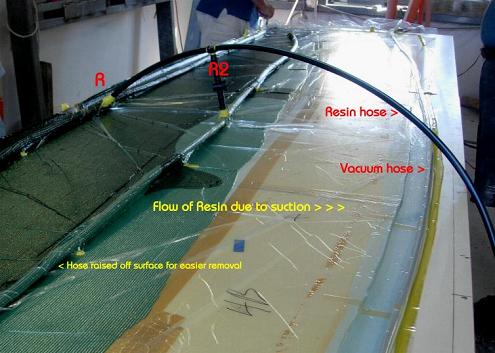

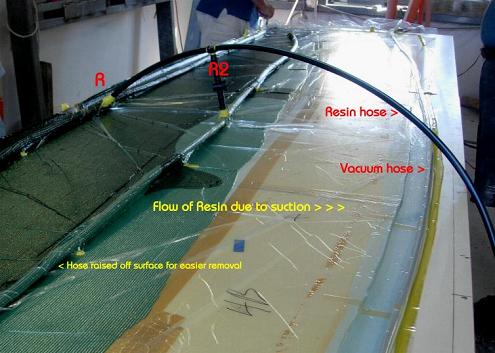

Once construction of the hull begins, workers lay the layers of fiberglass cloth in the mold and then a lightweight core of balsa wood followed by additional layers of cloth to meet the stated engineering requirements. A layer of plastic is then laid over the mold and the edges sealed, at which point a vacuum pump sucks all the air out of the mold. This forces the materials together tightly as an injection system pumps epoxy resin into the mold, filling in the voids and soaking the cloth.

In a few hours, the chemical reaction of the liquid epoxy hardens, creating the strong, hard shell of the boat. To further strengthen the epoxy, the whole boat is put into a large oven and “cooked” at a specific temperature for a period of time. Chemical engineers figure out the specific formulations of the epoxy resins, the temperatures they work at and the time it takes them to harden.

The mast and sails require similar engineering and science know-how. Sails are designed to work like the wings of an airplane – only vertically instead of horizontally. Most people think the wind just blows a boat along, but this isn’t exactly correct. It is the shape of the sails that produces power by allowing the wind to flow along the cloth thus creating pressure differences, which actually “pull” the boat toward the wind. Nowadays, the sails are made from composite plastics and the engineering of their strength and flexibility so that they can bend with the forces of the wind and sails and not break. The mast itself is made in a similar way as the hull of the boat, with cloth and epoxy resins.

When the body of the boat is complete, the real fun can begin. The mast and boom, the sails and the rigging are mounted and the boat is launched. Finally, it’s time to take it test sailing to see how the sailplan and the rest of the boat work together.

When the body of the boat is complete, the real fun can begin. The mast and boom, the sails and the rigging are mounted and the boat is launched. Finally, it’s time to take it test sailing to see how the sailplan and the rest of the boat work together.

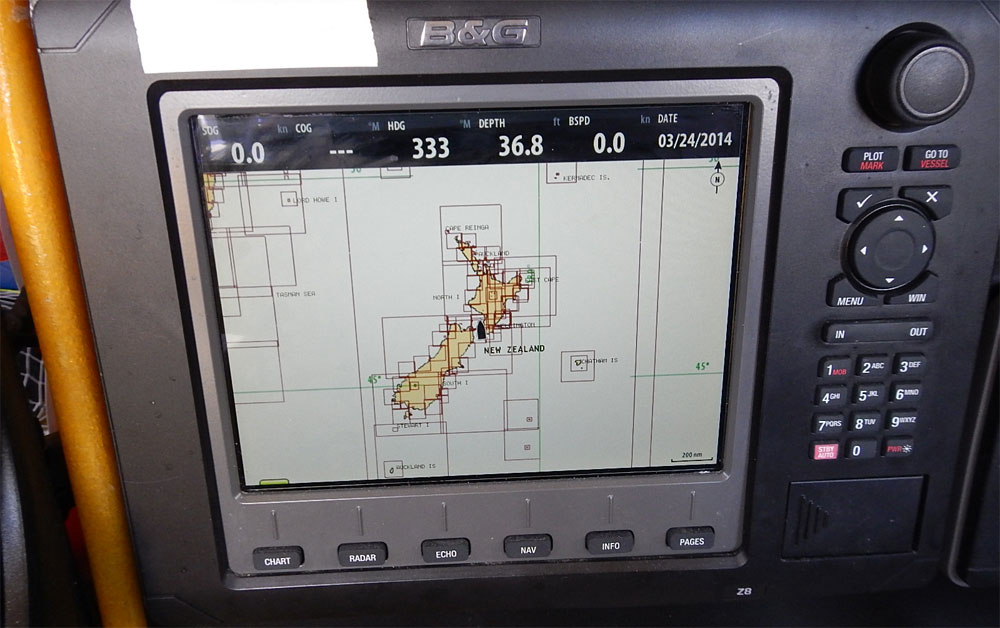

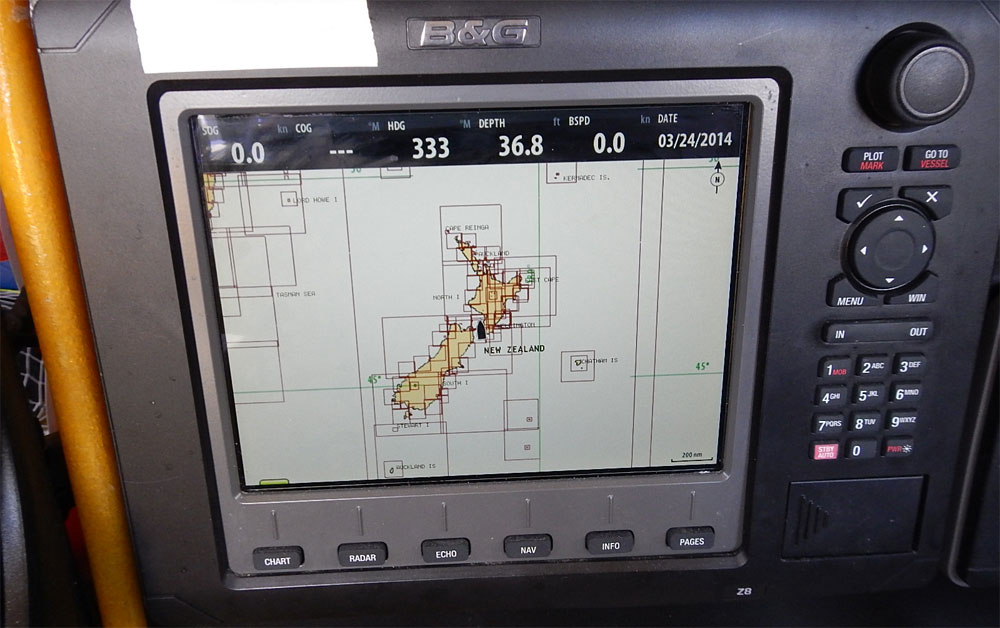

Once on the water, powerful onboard computers receive signals from multiple sensor devices that monitor everything from the angle and speed of the wind to the shape of the sails and the speed of the boat. These numbers are compared with computer-generated models to determine how well the boat is performing. Even with all this technical help though, the human sailor still must make the strategic refinements necessary for the boat to outpace its competitors and win a race.

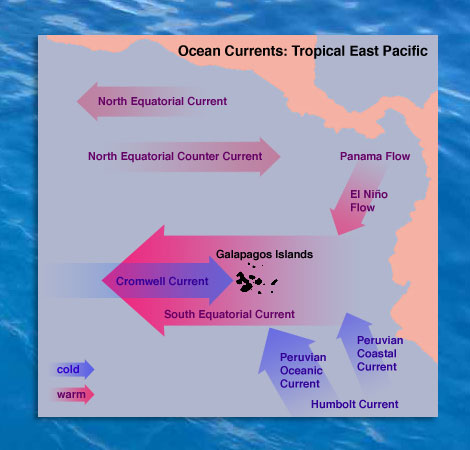

An experienced sailor today must master many skills. They must be conversant in many subjects before they can compete in a race like the Atlantic Cup. They need to have learned meteorology and how to anticipate changes in wind directions and speeds. They need enough knowledge of oceanography so that they can track currents and tides and how they dynamically shift and flow around a harbor or coast. They must have also learned how to work with computers so they can program, interpret and manage all the information the computers are capable of providing. And of course they must know their math and engineering, so they can keep the boat moving safely. Some good handyperson skills come in real handy too when called upon to fix things that break in the middle of a race (or when far from land.)

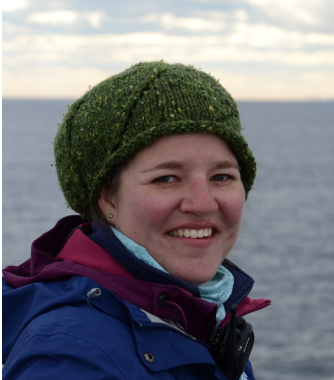

Bringing a boat into existence takes the work of many people with many different skills. Designers like Merf lead teams of skilled engineers, scientists and builders who all take pride in the building of fast and beautiful boats. And finally, there are the sailors, who use their wide range of technological skills and sailing instincts to help them win races like the Atlantic Cup.

Dragon, which Merf designed and will be co-skippering in the Atlantic Cup

Next time you hear your teachers (or parents) talk about the importance of STEM (Science, Technology, Engineering and Mathematics) education – you will be able to relate that to how it applies to the artful science of boat building.

SCIENCE: Weather science, chemical science, computer science, human physiology science

TECHNOLOGY: Computers, monitoring instruments, sail designs and shapes

ENGINERERING: Computers, composites, hardware, pulleys, loads, masts, sails and building

MATHEMATICS: Lots and lots of math. Numbers, computer calculations, engineering load calculations, speed calculations, parts and construction time calculations, cost and business calculations. Endless Math! (The more math you’re able to do in your head, the easier it will be to make these decisions.)

An even more complex set of calculations is necessary when it comes to the mast, which must support the power of the sails through the supporting cables called “shrouds.” There are many calculations to consider in how the shrouds spread the loads across the entire hull. All this has to be worked out so the boat and mast won’t fail in a powerful storm, yet still remain light enough to be competitive on the racecourse. There are always trade-offs to consider between strength and weight when making these important calculations and decisions.

An even more complex set of calculations is necessary when it comes to the mast, which must support the power of the sails through the supporting cables called “shrouds.” There are many calculations to consider in how the shrouds spread the loads across the entire hull. All this has to be worked out so the boat and mast won’t fail in a powerful storm, yet still remain light enough to be competitive on the racecourse. There are always trade-offs to consider between strength and weight when making these important calculations and decisions.

When the body of the boat is complete, the real fun can begin. The mast and boom, the sails and the rigging are mounted and the boat is launched. Finally, it’s time to take it test sailing to see how the sailplan and the rest of the boat work together.

When the body of the boat is complete, the real fun can begin. The mast and boom, the sails and the rigging are mounted and the boat is launched. Finally, it’s time to take it test sailing to see how the sailplan and the rest of the boat work together.

2. Check out the enhanced

2. Check out the enhanced

Photo by Billy Black

Photo by Billy Black

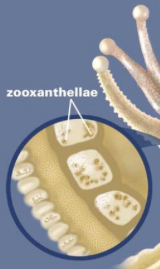

A coral reef is made up of many colonies of coral polyps which build the reef structure out of calcium carbonate. Tropical corals contain zooxanthellae, which is tiny algae that lives inside the coral where it photosynthesizes, creating food from sunlight. These algae are also what gives coral its brilliant and diverse colors. This means that coral can only occur in the “photic” zone, where sunlight penetrates the water. Corals polyps feed by extending stinging tentacles outwards to capture small prey and particles in the water column. Corals are related to other stinging animals including sea anemones and jellyfish.

A coral reef is made up of many colonies of coral polyps which build the reef structure out of calcium carbonate. Tropical corals contain zooxanthellae, which is tiny algae that lives inside the coral where it photosynthesizes, creating food from sunlight. These algae are also what gives coral its brilliant and diverse colors. This means that coral can only occur in the “photic” zone, where sunlight penetrates the water. Corals polyps feed by extending stinging tentacles outwards to capture small prey and particles in the water column. Corals are related to other stinging animals including sea anemones and jellyfish.

It’s early morning on Thursday and I’m heading down to the marina to put final provisions and water onto the boat and hopefully, by the time you read this, I will have departed. Our course will take us north towards the Yucatan passage that runs between

It’s early morning on Thursday and I’m heading down to the marina to put final provisions and water onto the boat and hopefully, by the time you read this, I will have departed. Our course will take us north towards the Yucatan passage that runs between